Magnetool, Inc. offers you high-performance magnetic filters designed to protect machinery and improve efficiency across various industrial processes. These magnetic filters are essential for removing ferrous contaminants, preventing damage to tools, and ensuring the quality of finished products. From fluid line filters to coolant filters, the use of magnetic technology provides a reliable solution to handle particles that could otherwise disrupt operations.

Magnetic Fluid Line Filters

Our Magnetic fluid line filters help reduce tool wear, protect workpieces, protect hydraulic pumps and media filters by trapping ferrous metal chips, filings, and dust. During machining operations such as drilling, milling, grinding, or broaching, contaminants can easily enter coolant systems, causing unnecessary damage. Any system using liquids, hydraulic oils, water based systems, etc. These magnet filters are installed on return lines to stop these particles from reaching reservoirs or pumps and circulating back to the workpiece. By using these magnet filters, downtime is reduced, leading to fewer tool breakages and more efficient production cycles.

These magnetic filters are virtually maintenance-free. The cleaning process is quick and easy, requiring occasional removal of collected particles. The components are made of aluminum and/or stainless steel and never need replacing. Whether using Alnico magnets as a standard or opting for Neodymium magnets for finer particles, these magnet filters ensure that coolant or lubrication systems remain clean without interrupting operations.

Ferrous Traps (In-Line) Magnetic Filters

Magnetool’s Ferrous Traps. Large Scale In-Line Magnetic Filters for large volume liquid flow rates. Steel and Stainless Steel construction bodies. These built-to-order magnetic filters can be customized to fit a wide variety of applications. Paper mills, food processing, hydraulic fluids, etc. Contact us today to learn more about how these magnetic filters can help improve your operations.

Magnetic Coolant Filters

Magnetool’s CSID Series magnetic coolant filters are designed for water-based coolant filtration. The magnet drum inside the filter attracts ferrous particles, creating a barrier that stops contaminants from continuing into the system. When the filter is clogged, the coolant level rises until it touches a probe, automatically triggering the drum to rotate. This simple yet efficient mechanism ensures that coolant keeps flowing while ferrous materials are pushed off the end of the drum.

For coolant systems using non-conducting oils, the CSO Series provides continuous filtration. The drum and urethane squeegee roll work together to separate oil from ferrous swarf, allowing clean oil to return to the system. These magnetic filters are built to last and maintain coolant quality without constant monitoring.

Special Coolant Filters

We also offer special coolant filters for high-volume applications. These magnetic filters include a larger magnet drum to handle increased amounts of ferrous particles. Centralized coolant systems benefit from cleaner fluids, extending tool life, reducing machine wear, and cutting down on coolant replacement costs. With cleaner coolants, you can also expect improved part finishes and reduced maintenance needs.

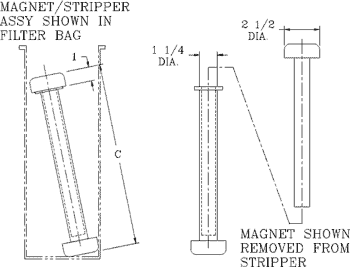

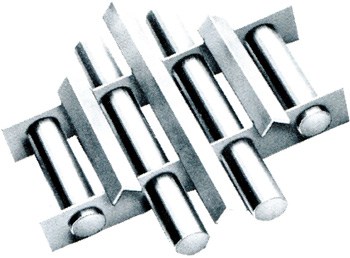

Filter Bag Magnets

Filter bag magnets are another effective option for removing ferrous particles from liquid systems. By increasing the life of filter bags, these magnet filters reduce the need for frequent replacements. They are easy to clean—simply remove the magnet tube from the sleeve, and the collected particles drop off in seconds. These magnetic filters retain their strength over time, providing consistent performance and longer filter life. Whether using Ceramic magnets as a standard or opting for Neodymium magnets for finer particles, or Alnico magnets for hot applications, your filter bags will last much longer.

“T” Series Tramp Iron Trap

The “T” Series Tramp Iron Trap is a solution for capturing ferrous particles in materials like sand, grain, pellets or liquids. Installed at the outlet of a chute, hopper, or coolant line, these magnet filters use ceramic magnets to trap particles as they flow by. They are designed for easy cleaning and require no maintenance, making them a convenient option for continuous operations. Available with Ceramic, Alnico, or Neodymium magnet materials.

Magnetic Hopper Grates

Magnetic hopper grates offer another way to filter out ferrous contaminants from dry or liquid materials. Available in various shapes and sizes, these grates are fitted with powerful magnets that ensure effective removal of particles. The durable construction ensures long-lasting performance, and different magnet types can be used depending on the application. Hopper Grate magnetic filters can be stacked for coarse and fine separation.

Catch Every Particle with Magnetool’s Magnetic Filters!

Magnetool, Inc.’s magnetic filters provide durable, reliable, and maintenance-free solutions for keeping your systems clean and running smoothly. If you need magnet filters for fluid lines, coolants, or hoppers, Magnetool has the right option for your needs. Contact us today to learn more about how these magnetic filters can help improve your operations.

Made in USA

Made in USA