- Removes ferrous particles from liquid flow increasing filter bag life.

- All 304 stainless steel sturdy construction resists wear and damage.

- EPDM (Ethylene Propylene Diene M) rubber bumpers to protect fabric bags.

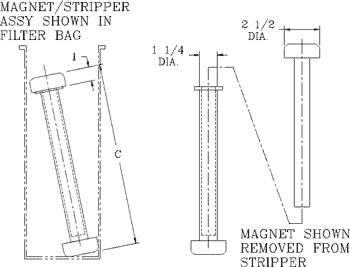

- Easy cleaning. Remove magnet tube from stripper sleeve. Magnetic particles drop off into waste pan. Less than 5 seconds to clean.

- Magnet assemblies never lose power. Frequent magnet cleaning results in lower disposal rate of the filter bags.

- Filter bag magnets have been reported to reduce bag usage by up to 15:1.

- Typical savings of 6:1 to 12:1 are common.

Ordering Information

Filter Bag Magnets

| Model | Bag Size | Bag Dia. x Lgth. | Magnet Length |

| 8282-08-15 | 1 | 7" x 16-1/2" | 15" |

| 8282-08-30 | 2 & 9 | 7" x 32" | 30" |

| 8282-08-8 | 3 | 4" x 8" | 8" |

| 8282-08-14 | 4 | 4" x 14" | 14" |

| 8282-08-20 | 8 | 5.6" x 21" | 20" |

| 8282-08-24 | 24" | ||

| 8282-08-34 | 12 | 8.2" x 32" | 34" |

Standard Filter Bag Magnets utilize Ceramic Magnets.

Add “N” suffix to part number for Neodymium Magnets.

Add “A” suffix to part number for Alnico Magnets.

Filter Bag Magnets Info

| Ceramic | Neodymium | Alnico | |

| Gauss on Magnet Tube Surface | 1200 Gauss | 6300 Gauss | 1350 Gauss |

| Capacity (steel chips) per 4" of magnet length | 1 lb | 2.45 lbs | 1.55 lbs |

| Pull Force (for comparison purposes) | 25 lbs | 125 lbs | 35 lbs |

| Effective Distance (for comparison purposes) | 1-1/4" | 1-1/4" | 3" |

| Service Temperature (EPDM service temp = 300°F) | 300°F | 176°F | 300°F |

Deep Field Neodymium Versions available on request – contact engineering.

Made in USA

Made in USA